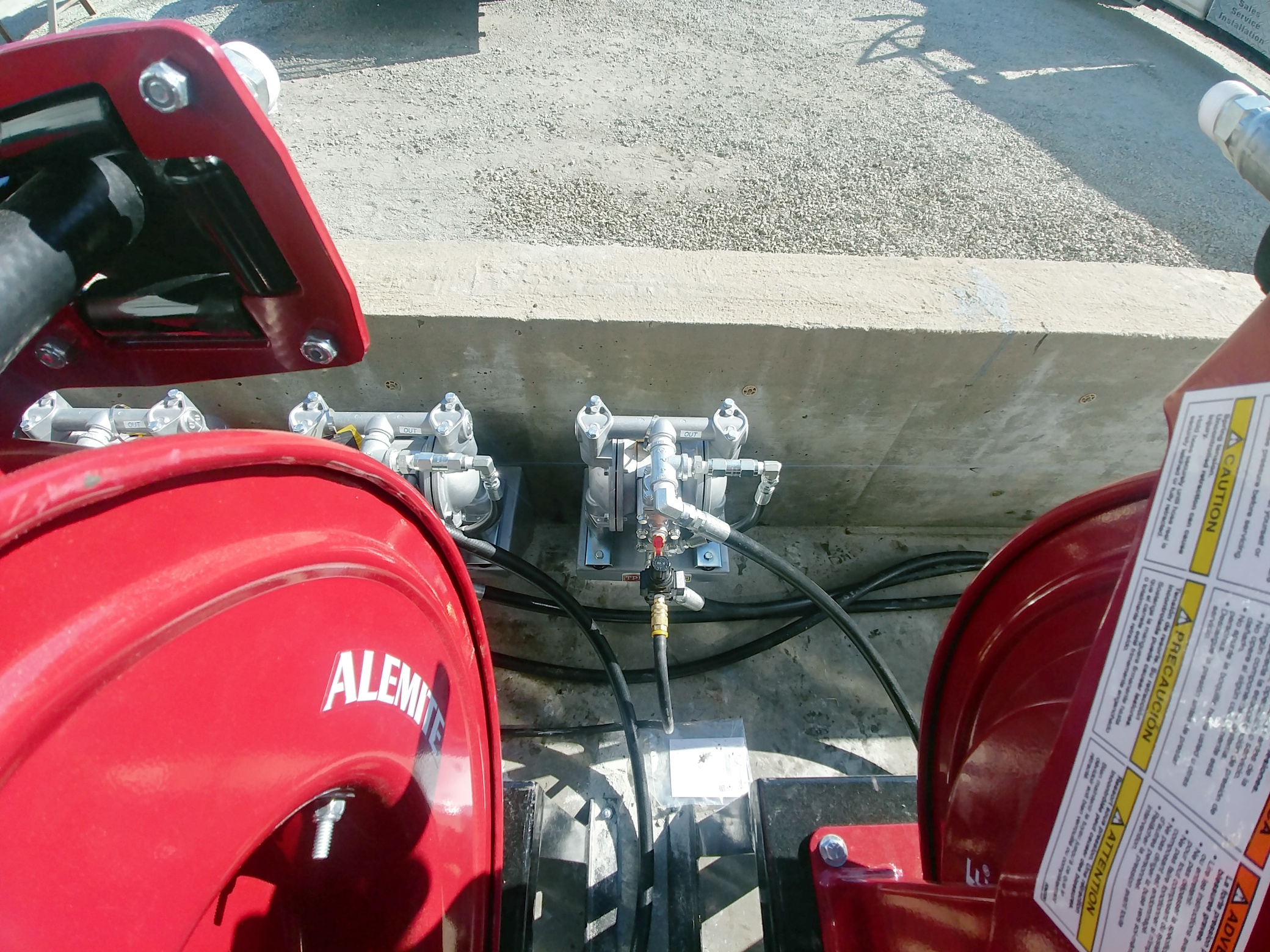

Lube System Installations

For business owners who have shops with multiple bays that require the same oil product, or who want the tanks to be remote from the reels, finding the right company to install their lubrication system is key to creating long-term efficiency and profitability. During our on-site consultation, we discuss tank and reel mounting and locations, metering options, and potential oil tubing (dependent upon your specific shop layout). We are sure to address the potential for pressure loss and thermal temperature changes if oil tubing is needed.

The TPL Difference

What sets us apart from the competition? We not only install lube systems, we custom fabricate reel brackets to counter high ceilings or challenging shop configurations, which can often prevent easy use of the lubrication hoses themselves. We also fabricate custom oil sinks, meter hangers, and wall and floor mount stands.

Request An Install Quote:

Recent posts

Why Your Grease Pump Isn't Working - A Guide

As 2024 rolls in and we all get back into our routines, it’s common to encounter equipment issues leftover from December. But now, that malfunctional grease pump is slowing – or even halting – your work day. The result is operational downtime, which can put a damper on even the best New Year’s resolutions. Our short guide to diagnosing your grease pump problems can help.

Why TPL Lube Trucks Are The Most Reliable

When you have a lube truck, skid, or system, reliability is a product characteristic that isn’t just expected – it’s non-negotiable. Your fluid exchange equipment needs to work reliably. But what does that mean? Learn three, simple ways that TPL lube trucks (and other lube equipment) are the most-reliable in the industry.

The Four Main Components You Should Be Checking: A Parts Maintenance Guide

While it may seem counterproductive to put extra time towards equipment maintenance, performing regular service on your equipment parts is vital to keep them running effectively and efficient during peak production seasons. Check out our Parts Maintenance Guide for more.

Lube Trucks

Lube Trucks Water Trucks

Water Trucks Fuel Lube Trucks

Fuel Lube Trucks Lube Trailers

Lube Trailers Lube Skids

Lube Skids Hook Lift Package

Hook Lift Package On-Demand Inventory

On-Demand Inventory Lubrication System Installations

Lubrication System Installations Tank Packages

Tank Packages Truck Restoration

Truck Restoration Lift Installations

Lift Installations Truck Repair

Truck Repair System Repairs

System Repairs Our Team

Our Team Careers

Careers TPL Media

TPL Media